Glass marbles, not only beautiful but also popular in games and decoration, have become an essential part of daily life. The production process of these marbles requires meticulous attention to detail and high technical skill. Below is a detailed overview of the process for making glass marbles.

Required Materials

- Raw Glass: Usually made from silica (glass sand), soda, and lime. These materials are mixed to create a glass batch.

- Colorants: To produce various colors for the marbles.

- High Temperature: Necessary for melting the glass.

Steps in the Process

- Preparing the Raw Materials:

- The glass ingredients are mixed in specific proportions, depending on the desired color and properties of the marbles.

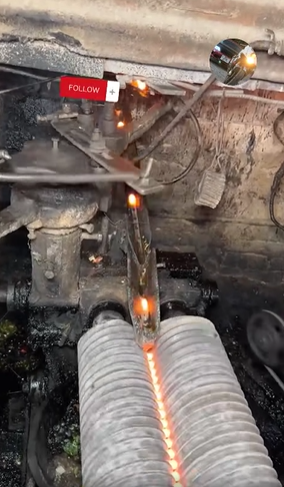

- Melting the Glass:

- The glass batch is placed in a furnace and heated to a high temperature, around 1400-1600°C, until it becomes liquid. This process can take approximately 24-48 hours to achieve a homogeneous mixture.

- Shaping the Marbles:

- The molten glass is taken out and poured into molds to form the marbles. The molds can be made of steel or other metals, allowing for various sizes.

- A popular technique involves using a glass-blowing tool, where the craftsman blows into a pipe to create the desired marble size.

- Cooling:

- After shaping, the marbles are slowly cooled in an annealing oven (lehr). This step is crucial to avoid cracking due to thermal shock.

- Finishing and Polishing:

- Once cooled, the marbles are inspected, and any defects are removed. The marbles are then polished to achieve a smooth and shiny surface.

- If necessary, a protective coating may be applied to enhance durability.

- Quality Control:

- Each marble undergoes thorough inspection for size, color, and finish. Any marbles that do not meet standards are discarded.

- Packaging:

- Finally, the marbles that pass quality checks are packaged and prepared for distribution to consumers.

Notes on Making Glass Marbles

- Safety Procedures: The melting and handling of glass require strict adherence to occupational safety regulations.

- Quality Control: Ensuring that each marble meets quality and safety standards before reaching the market is essential.

- Processing Techniques: The manufacturing techniques should be carried out by skilled artisans to ensure the highest quality final product.

Conclusion

The process of producing glass marbles is an art that combines science and technique. From preparing raw materials to quality inspection, each step demands precision and professionalism. Glass marbles not only provide value in games and decoration but also showcase the craftsmanship of artisans in creating beautiful and durable products. Understanding this process will help consumers appreciate the products they use daily even more.